“From Sustainability Reporting to Sustainability Management Control” is the title of the 17th Annual International Conference of the Environmental and Sustainability Management Accounting Network (EMAN) to be held in Rotterdam at the end of March this year. The conference’s theme highlights the urgent need for businesses and academics to move from “why” questions such as “why companies are involved in sustainability issues” to “how” questions including: “How are appropriate data obtained and how are they used to influence management decision making, management control, performance management and incentive systems when assessing the success of company sustainability?” (Citations from conference website).

To answer such “how” questions in reference to the chemical industry, the research project InReff (Integrated Resource Efficiency Analysis for Reducing Climate Impacts in the Chemical Industry) was set up in 2012. From an accounting methods perspective, the project might seem a bit overly technical given its foundation in process engineering, industrial ecology, operations research, and information technologies. But, the lack of STEM (science, technology, engineering, and mathematics) might be exactly one reason why “sustainability accounting” struggles to move from “why” to “how”.

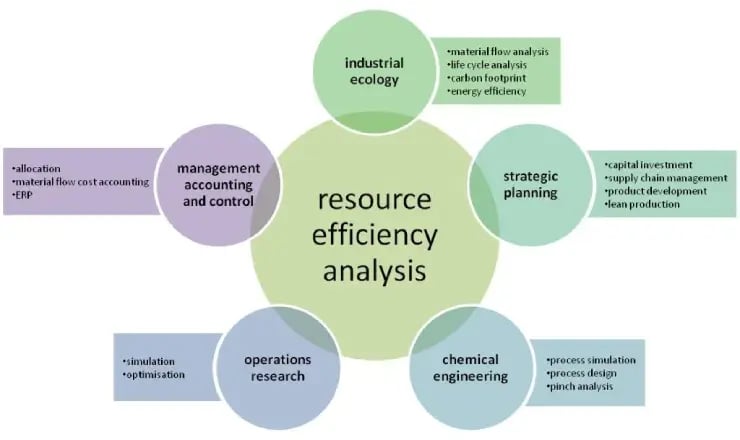

Continuous increases in resource use efficiency, i.e., minimization of natural resource input per unit of production output, will only be achieved if aspects of resource efficiency are available at all levels of decision making within the chemical industry. An initial analysis and the first derivations of resource efficiency improvement for production and product systems can be based on average material and energy inputs and outputs found for the systems over a given time, or, in other words, by means of ‘conventional’ sustainability accounting and reporting. However, this black box approach is not sufficient anymore if resource efficiency measures require the adaptation of process parameters and programs, the inclusion of material loops and recycling, or the often non-linear interaction of various processes. In such cases, resource efficiency analysis (and sustainability control) might even have to dig down to the level of thermodynamic and physical causalities at the process design level.

The InReff project tries to achieve this in terms of project and research design. The project was designed in an inter- and trans-disciplinary manner, and requires the collaboration and joint problem solving approaches of:

- three producers from the chemical industry including one SME (Sachtleben Chemie GmbH, Duisburg; H.C. Starck GmbH, Goslar; Worlée Chemie, Lauenburg).

- an IT company offering solutions and software in the field of life cycle thinking and material flow based sustainability control (ifu Institut für Umweltinformatik Hamburg GmbH).

- two academic partners representing chemical and thermal engineering (TU Braunschweig, Institute for Chemical and Thermal Process Engineering) as well as industrial ecology and operations research (Pforzheim University, Institute for Industrial Ecology).

- further associated partners from business, IT, and academia.

The research design combines several methods, including practitioner surveys, in-depth case studies, methodological enhancements, and IT-based integration of relevant tools and methods in order to answer research questions, including:

- What information is missing for proper resource efficiency decision making in the chemical industry?

- What does the ideal of a typical resource efficiency analysis in the chemical industry look like?

- How are methods from management control, industrial ecology, chemical engineering, and operations research integrated (see figure below)?

At the current stage, several intermediate objectives have been achieved and will be published in forthcoming academic papers, including the proceedings of the upcoming 21st CIRP Conference on Life Cycle Engineering in Trondheim this June. These objectives include:

- the blueprint for an ideal typical resource efficiency analysis in the chemical industry

- an IT-based linkage of material flow networks and flow sheet simulation that integrates the full power of process engineering models into resource efficiency assessments

- identification of initial resource efficiency improvements at industry partners’ sites, e.g., complete avoidance of some recycling streams through better process control and readjustment of process parameters, and reduced energy demand and lower carbon emissions due to optimized oven programs.

As InReff is an ongoing project, more interesting results and insights can be expected during 2014 and 2015 and will certainly also appear in this blog. InReff will thus help to understand “how” to actually increase resource efficiency in the chemical industry and “how” information gathering and assessment for sustainability control does work.

Acknowledgements

The InReff project is funded by the German Federal Ministry for Education and Research (BMBF) (Fkz. 01RC1111) within the “Technologies for Sustainability and Climate Protection – Chemical Processes” program and is administered by the German Aerospace Center (DLR).

For further information and involvement please contact this author or Nick Denz (n.denz(at)ifu.com).