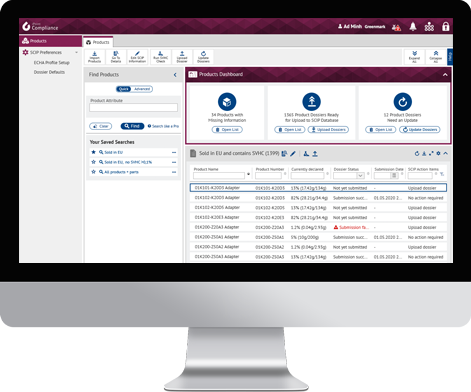

Our Reusability, Recyclability, Recoverability (RRR) Compliance Solution

Complying with the RRR directive causes high labor costs for automotive OEMs and suppliers. Suppliers not only need to create material lists, they also have to define parts that are subject to their own rules, such as wheels. There are also rules for parts that can be removed and reused before recycling to be considered.

Meet reuse and recycling rates

iPoint’s RRR software solution supports you in gathering the necessary information and simulating various recycling processes, thus enabling you to meet the designated reuse and recycling rates. It also identifies detailed material information for Reusability, Recyclability, Recoverability compliance requirements.

Simulates processes and calculate RRR quotas

With iPoint’s RRR software solution, the physical removal of prototypes is no longer necessary. It simulates different processes, offering complete support in defining pre-treatment, disassembly and shredding procedures as well as documenting the material flow for all processes. The software calculates Reusability, Recyclability, Recoverability quotas in accordance with ISO 22628 and China ELV (GB/T 30512-2014) for the automotive industry.

Expand the Reusability, Recyclability, Recoverability software solution with DfE and LCA

Additionally, the iPoint RRR compliance software solution can be expanded to other iPoint solutions, e.g. for DfE (Design for Environment) and LCA (Life Cycle Assessment).

Benefits

Features

Functionalities

Discover the iPoint Suite

How Toyota North America ensures the compliance of its products

iPoint Compliance

Discover how Toyota North America uses iPoint Compliance from iPoint to create the transparency businesses need to manage what they already measure.

What is RRR – Reusability, Recyclability, Recoverability of Motor Vehicles?

In accordance with the European ELV Directive 2000/53/EC, the European Reusability, Recyclability, Recoverability (RRR) Directive 2005/64/EC lays down administrative and technical provisions for the type-approval of motor vehicles.

The aim is to ensure that the component parts and materials of vehicles are reusable, recyclable, and recoverable in designated minimum percentages.

Among other things, the directive mandates manufacturers to put in place satisfactory arrangements and procedures to manage all information they receive from their suppliers. Type-approval is only granted to such vehicle types that satisfy the reusability, recyclability, and recoverability requirements of the Directive.