Our IMDS Compliance Solution

Automotive manufacturers have developed the “International Material Data System” (IMDS) to comply with the EU ELV requirements. According to current international regulations and guidelines for End-of-Life Vehicles (ELV), certain materials (e.g. heavy metals) may not be used. Listing all materials used by automotive manufacturers and suppliers is a complex task, considering that approximately 30,000 components are implemented in each car model. It was the first industry-level tool adopted by many relevant automotive industry players, including OEMs and suppliers around the globe.

Leverage your IMDS Data with iPoint

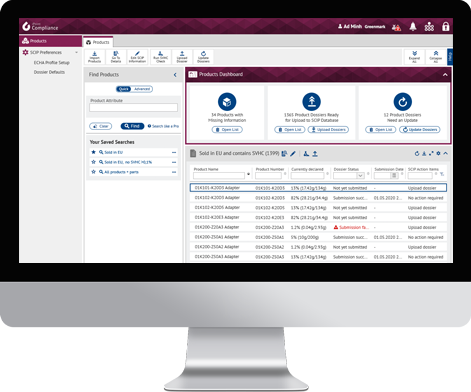

IMDS effectively helped many organizations better utilize data required to comply with the ELV Directive in the early years, and later to cover even more regulatory requirements such as REACH, US TSCA, California Prop 65/SCP, and WFD (SCIP). With the iPoint compliance solution for IMDS, you have the ideal tools for configuring and automating your ELV processes which cuts costs considerably.

Collect

Analyze

Report

Use IMDS Data and automatically create Product Carbon Footprints

iPoint Product Sustainability enables you to combine compliance and sustainability.

Discover the iPoint Suite

Case Study Hella

iPoint Compliance

Watch the video with Oliver Schmid, Material Compliance Manager at automotive supplier Hella, and learn from the best practice example Hella about data collection for compliance and sustainability in the automotive industry.

What is IMDS?

A group of automotive manufacturers have developed the International Material Data System (IMDS) that is used throughout the automotive supply chain to comply with legal requirements. IMDS is an online- based archiving, communication and administrative system that is used to access and deliver material data sheets. The material data sheets in IMDS allow to identify all used materials which is necessary for the later recycling of the vehicle part.

All suppliers participating in the manufacturing process of a vehicle have to transfer their material data into the IMDS system. This includes ensuring that the data is accurate and complete. These mainly manual processes are costly, time-consuming, and error-prone. Furthermore, specific OEMs also have additional portals that require data. Not to forget the increasingly required CAMDS system. This puts considerable pressure on value chains.